What are Embroidery Stabilizers & How Are They Used?

So... What Exactly is a Stabilizer?

Embroidery stabilizers are simply an applied weave that is added to various fabric types to help reduce or eliminate bunching and puckering. They are also important in reducing the ability of the stitches to take on the texture of the fabric that they are being applied to or sinking too deeply into the fabric. Many lighter fabrics are especially susceptible to these issues, since they lack the stiffness of other materials such as leather. The application of the stabilizer can either be above or below the fabric (or a combination of both), which helps to cut down or eliminate these issues and provides a much more steady medium to work your embroidery designs onto!

Topping Versus Backing Stabilizers

Stabilizers are almost exclusively used in machine embroidery and the use of topping and backing stabilizers are exactly what their names suggest.

Topping stabilizers are typically placed over your design, the main purpose for these applications is to help prevent the stitching from 'sinking' into your fabric. Normally topping is only used with fabrics that are more 'stitch absorbent' or textured (good examples being terry cloth or wool fabrics) and these topping stabilizers will typically come in wash away and tear away types.

Backing stabilizers, on the other hand, are recommended for almost every fabric, and this is with very few exceptions. Backing types assist your fabric to help maintain its structural and physical integrity while being embroidered. They will also allows your designs to keep their shape after being laundered.

The focus of this blog post will be predominately on backing stabilizers.

The Material & The Embroidery Design You Use Will Determine The Stabilizer to Use

Before you get started, there are three things you will need to consider.

These three factors are very important when selecting the right stabilizer...

- The type of fabric you plan to embroider upon

- Your fabrics density

- Lastly... the stitch density

When choosing a fabric type, you'll want to keep an eye out on the stitch-count of the fabric itself, as this will effect how thick a stabilizer you will need and will also effect the speed at which you're machine should stitch out a pattern effectively onto that fabric. This is an important consideration, as when more tension is applied during an embroidery, the more likely you can break your thread during the embroidery process at higher speeds.

With fabric density, some fabrics may require two stabilizers, some may require none. Standard fabrics will usually just require one type of stabilizer. Your embroidery fabric is always your starting point so make sure you do your research on what stabilizers are compatible with your fabric.

With stitch density, the higher the density of the stitches, the thicker the stabilizer needs to be to add in stability. The less stable the fabric, the more stability you'll need to apply.

LETS GET STARTED! - The Different Stabilizers

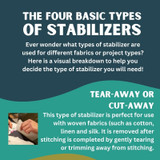

We will cover the three main types of stabilizers (cut away, tear away and wash away) as well as two additional stabilizers that are a little less universal (heat away and spray on).

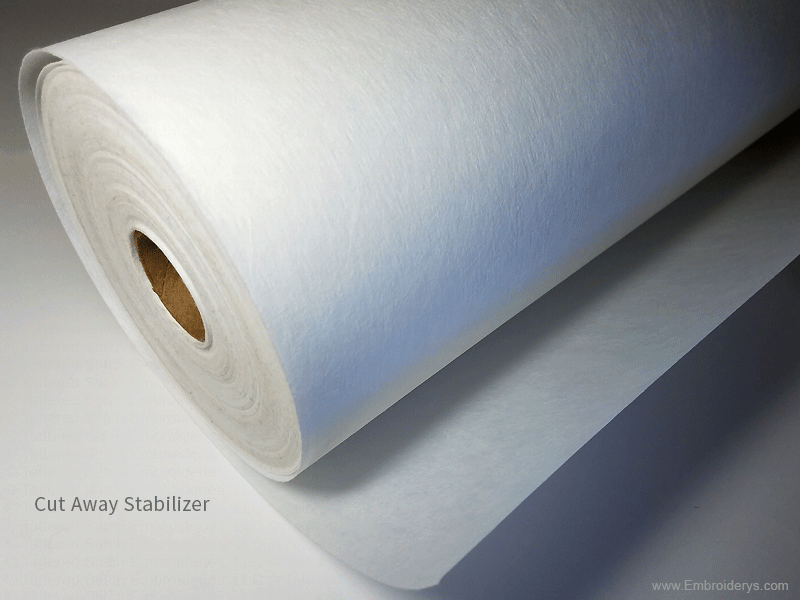

Cut Away Stabilizer

A cut-away stabilizer is a product that will not be totally removed upon completion. The excess stabilizer will be trimmed away, however, the stabilizer that was stitched upon will stay permanently attached to the fabric.

Cut-away stabilizers are preferred by many embroiderers, mainly because of the way the final project will feel on the skin. Since there’s no removal of the majority of the material, there are no jagged edges that can irritate the skin. They also add an extra feature of keeping the design stable during wash cycles.

Cut-away stabilizers are quite versatile and are great especially for delicate fabrics, with the exception of silk. However they are generally not recommended for loose-knit or sheer materials. This is because they will be visible through these materials. Instead, look into a polyester or nylon mesh cut-away stabilizer, these are made specifically to be invisible through see-through fabrics.

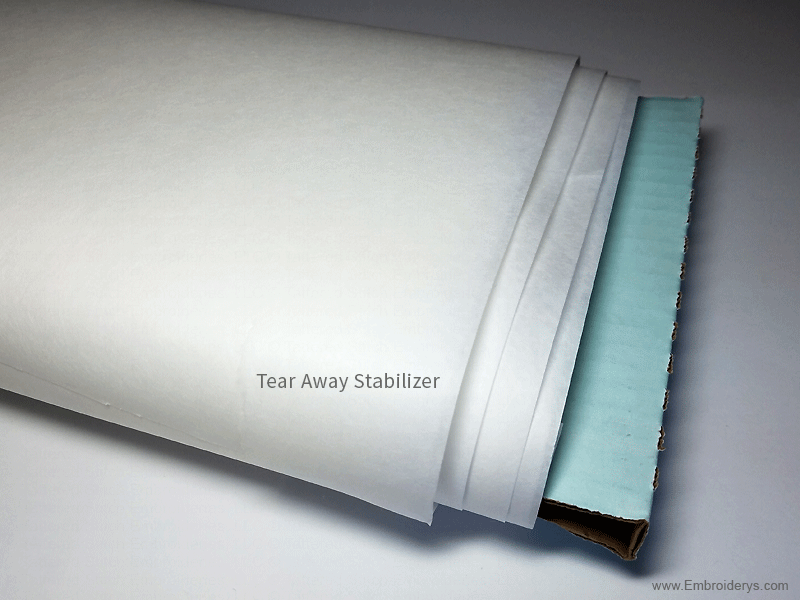

Tear Away Stabilizer

The quickest and easiest to remove of the stabilizers. They are simply adhered to the back of your embroidery design during the embroidery with temporary stitches, then can be torn right off.

These types of stabilizers are best used with a heftier fabrics. The simple act of tearing may be a little bit harsh for more delicate fabrics.

Generally categorized by weight (as most stabilizers are), tear-away stabilizers will require that if you’re working with heavier fabrics, a heavy weight tear-away stabilizer is required.

Tear-away stabilizers are a great, cost-effective option, especially if you’re going to be embroidering on standard stable fabrics!

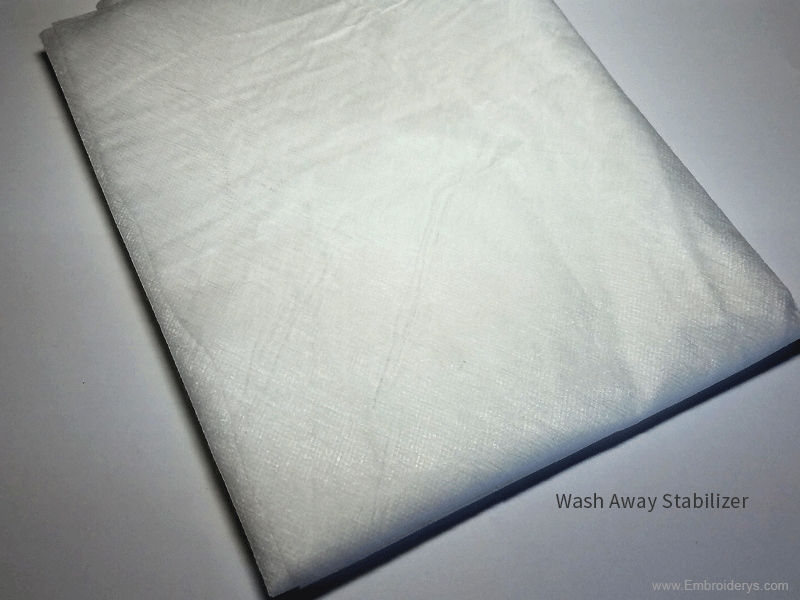

Wash Away Stabilizer

Use of water soluble stabilizers are a little less universally loved than cut-away or tear-away stabilizers. But that does not mean they are any less useful for specific projects. These are often considered the perfect 'invisible' stabilizer. Typically, they are used with either more delicate, sheerer materials or pieces that require constant wash-and-wear and stand-alone lace designs.

Wash-away stabilizers are known for their resilience, transparency and water solubility. So these are best used in cases where your project requires there be no traces of the stabilizer left afterward.

Heat Away Stabilizer

This type of stabilizer is the one of the go-to for your fussier fabrics. Heat-away stabilizers are perfect for projects that are too fragile for tear-away's, and too sheer for cut-away as well as non-washable lace.

There are two types of heat-away stabilizers (woven and filmy backed). Woven stabilizers will flake off with heat and the filmy stabilizers will dissolve completely.

Heat-away stabilizers are less universally applicable than the standard cut or tear-away stabilizers, as they will not provide as much support.

Spray On Stabilizer

One of the more modern-day types of 'invisible' stabilizer are the spray-on stabilizers. These are often used to stiffen fabric temporarily without the use of any additional material (much like starching a shirt or pants).

Spray-on stabilizers are perhaps one of the most convenient types available. It should be noted though, that this type of stabilizer is best utilized on lighter fabrics that have less need for serious stabilization.

Many embroiderers will also avoid spray-on stabilizers when it comes to expensive materials, such as silk. But mainly, this is just an extra precaution on their part and many people have used spray-on stabilizers on all kinds of materials without issues.

Practice, Practice, Practice!

It cannot be said often enough, but with practice comes understanding and with understanding, comes wisdom. This wisdom can be sought after in books, online and in videos, but nothing really allows you to focus your skills better than the act of doing!

Trial by error may be a bit tedious at times but it will always enforce a better understanding of what DOES NOT work better than any other discipline.

My recommendation would be to journal your experiments in the use of fabric stabilizers. Keep samples of various fabric types that have worked and the techniques you used to achieve these outcomes.

When a new project comes around the corner (and they always do), you will have the tools you need to make your latest creation as simple and carefree as possible right from the get-go!

Recent Posts

-

Our 5 Most Popular Projects! - Tattered Stitch Embroideries

Want to view some of our most popular in-the-hoop designs? Look no further!...Placemats - https://ww …Dec 14th 2023 -

Our Survey Results... What Embroidery Machine Are You Using?

We wanted you to get an idea of what embroidery machine's were considered clients personal choices, …Oct 19th 2023 -

Look Who's Creating - A Witch!

With Halloween getting close at hand, it is time to get busy coming up with unique and enterta …Sep 19th 2023